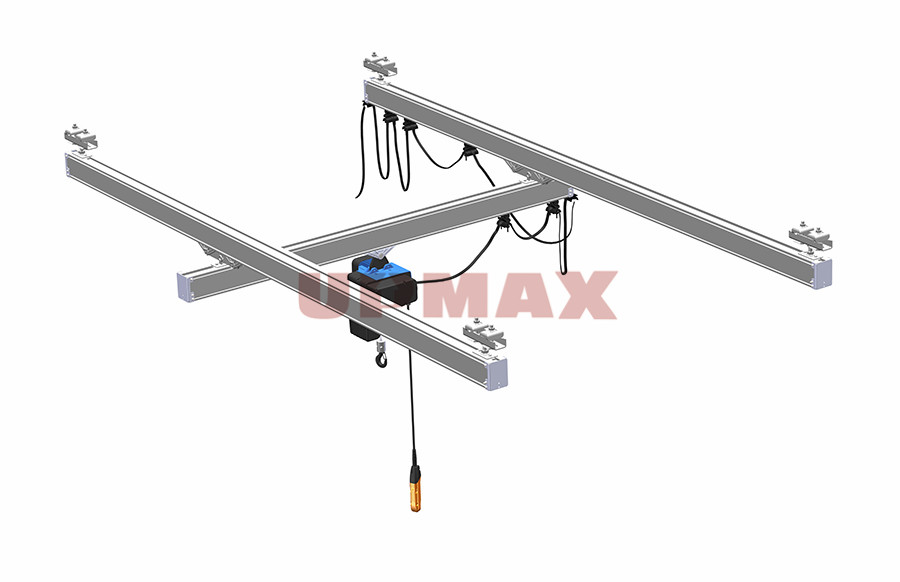

铝合金轨道起重机介绍Aluminium alloy track cranes introduction

铝合金轨道起重机,是一种主要应用铝合金行走轨道及滑车,用碳钢做结构支撑或配件,铝合金与碳钢组合的一种新型轻载起重设备。

铝合金轨道起重机载重量从125kg到2000kg。顺畅平稳的系统让您操作更加便捷、更符合人体工程学原理,更新,更好运行更顺畅。标准模块化配件让安装和改造更加便捷。低摩擦系数让铝合金轨道起重机让重载荷的搬运更轻松。尼轮车轮与铝合金表面的摩擦噪声等级更低。系统几乎免维护,更有多重二次保护装置可选。因其模块化的系统设计,让规划更自由;跟钢轨型材的独特组合,让吊点之间获得更大间距,更加节约成本。

铝合金轨道起重机符合人体工程学的工位设计对生产力有直接影响,让您的生产率获益良多,为新轻型起重机系统重新定义了顺畅运行的特征,让您的吊装更加轻松自如。

The aluminum alloy track crane is a new type of light load hoisting equipment which mainly applies the aluminum alloy walking track and the pulley, USES the carbon steel as the structure support or the accessory, the aluminum alloy and the carbon steel combination.

The load of aluminum alloy rail crane ranges from 125kg to 2000kg.Smooth and smooth system allows you to operate more convenient, more ergonomic principles, update, better operation and more smooth.Standard modular parts make installation and retrofit easier.The low friction coefficient makes the aluminum alloy rail crane easier to carry heavy loads.The friction noise level between the wheel and the aluminum alloy surface is lower.The system is almost maintenance-free and has multiple secondary protection options.Because of its modular system design, let the planning more free;With the unique combination of rail profile, so that the lifting point between the greater space, more cost saving.

The ergonomic station design of the aluminum alloy rail crane has a direct impact on productivity and benefits your productivity. It redefines the characteristics of smooth operation for the new lightweight crane system and makes your hoisting more comfortable.

产品特点Features

自重轻、抗弯强度较高 Light weight, high bending strength

铝合金标准组件有四种规格的不同型材轨道,承载能力最大达到2000kg,精密加工的铝合金型材及结构件安装简单、模块化、并保持运行更顺畅。封闭设计的铝合金轨道重量轻却有较高的抗弯强度,而且更好的耐磨性。由于表面阳性电镀处理以及自身的防腐特性。这种结构用于洁净厂房及汽车生产线、食品、电子业,并且较轻的自重是值得考虑的因素。

The aluminum alloy standard component has four different profile tracks of different specifications, with the maximum bearing capacity up to 2000kg. The precision machined aluminum profile and structural parts are easy to install, modular, and keep running smoothly. The aluminum alloy track with closed design is light in weight but has higher bending strength and better wear resistance. Because the surface positive electroplating treatment and its own anti-corrosion characteristics. This structure is used to clean plant and automobile production lines, food, electronics, and the light weight is worth considering.

铝合金轨道摩擦阻力更小Aluminum alloy track friction resistance is smaller

不仅轨道的加工精度较高,精密联接部件同样是载荷运行安静顺畅的关键。运行小车采用尼龙车轮结构、车轮通用化、标准化。正是因为标准化组件的设计,行走小车可以在日后配上电驱动实现电驱运行,甚至他可以匹配其他各种不同截面的型材轨道。

The aluminum alloy track friction resistance is smaller, not only the track processing accuracy is higher, the precise connection component is also the key to the load operation is quiet and smooth. The trolley is made of nylon wheel structure, which is generalized and standardized. Because of the design of standardized components, the walking car can be equipped with electric drive to realize electric drive in the future, and it can even match the profile track of various other sections.